CEPL is pleased to announce that we are the sole-distributor of the FluidFlow software in India and the Middle East.

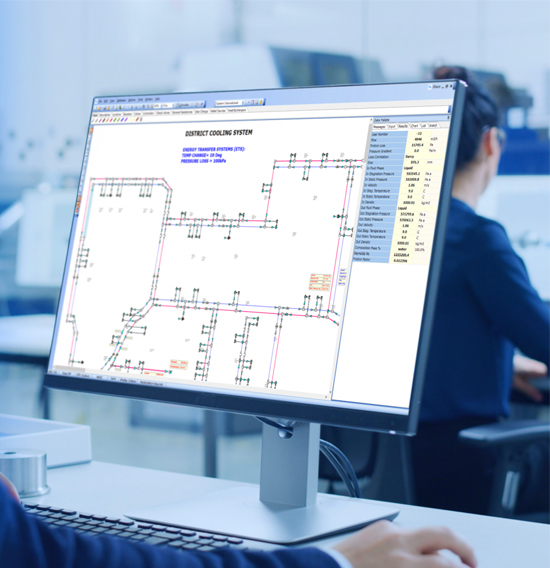

FluidFlow Software is a powerful tool for process engineering that allows you to model the fluid behaviour within complex piping systems and accurately predicts how the system will work for a given set of boundary conditions. The software uses a number of well-established models and correlations to solve the piping systems and boasts a comprehensive database of fluids, pumps, valves, pipes, and other components.

FluidFlow is a modular software product meaning you can choose the calculation modules which are relevant to your company and industry. You can therefore model and fluid type or phase state within one single model. This means you don’t have to purchase or learn how to use multiple software programs and spend extra time creating multiple models in separate programs to complete your design analysis.

Ease Of Use

Intuitive User Interface, short learning curve & rapid model construction helps save up to 80% time versus spreadsheets

Comprehensive databases of fluids, pipes and fittings included as standard. Quickly & easily add your own fluids and components to master databases

Modular environment allows users to simulate liquid, gas, slurry or two-phase flow

Calculation Accuracy

Proven calculation reliability helps engineers create accurate designs and avoid costly errors

Designed and quality assured to enable users to produce economic and technically sound models, in the shortest possible time

FluidFlow is rigorously tested and verified against published data and real-world operating systems on a continuous basis

Auto Sizing Technology

FluidFlow offers a fast and effective approach to automatically sizing piping and associated equipment

Accelerate the design process and avoid unnecessary over-sizing of piping and equipment, saving both design time and capital cost

FluidFlow will propose the most economical pipe size based on physical property data, capital equipment cost and energy costs

Thermal Energy Transfer

Heat transfer functionality and database of insulation materials included on all FluidFlow modules, as standard.

Consider conduction, radiation, and convection losses and optimize energy usage.

Model shell and tube exchangers, plate exchangers, coils and autoclaves.

Customisable Reports

Communicate your designs quickly and effectively with fully customisable reports.

Personalise reports with company logos and standard report format.

Export complete flowsheet, bill of materials and generate reports in PDF, Word & Excel.

PCF File Import

Piping Component Files (.pcf’s) are file formats generated by various CAD tools such as SmartPlant 3D, CADWorx, Solidworks, Autodesk Inventor, Plant4D, Autoplant, Smart 3D and more.

Put these files to even further use by importing PCF Files to FluidFlow

Streamline design process and significantly reducing time required to solve and build piping systems.

FluidFlow Modules

1. Liquid Module

This module is used by engineers to calculate operating pressures, pressure losses, and flow distribution in liquid piping transportation systems. FluidFlow can model any component that a user is likely to come across. Users can choose from three pipe pressure loss models; Moody (Darcy-Weisbach), Hazen Williams or Fixed Friction Factor (Darcy) The module includes a powerful equipment sizing functionality while also allowing you to model vendor pumps in your systems and considers changes in pump speed and impeller diameter. FluidFlow automatically creates the system resistance curve for all pipes in your piping system. The liquid module can be used to model a wide range of systems such as cooling water plant, district heating mains, liquid nitrogen plant, LNG plant, mine dewatering systems, fire protection systems, utility systems, etc.

2. Gas Module

Design of gas pipe flow systems can often present complex challenges which can be overcome with the help of FluidFlow which takes into account the pressure, temperature, density, enthalpy, velocity and other physical properties that are constantly changing in a piping network in which a gas is flowing. Users can choose from the available equations of state; Benedict-Webb-Rubin, Peng-Robinson, Lee Kesler. The software automatically detects choked flow conditions as well as taking into account the Joule-Thomson effect.

3. Two-Phase (Liquid-Gas) Module

FluidFlow can be used to calculate pressure losses and flow distribution in two-phase pipe flow systems which can often be quite complex. The software can be used to model fixed or changing vapor quality systems with heat transfer included. Calculation methods include Lockhart-Martinelli, Friedel, Muller Steinberg and Heck, Drift Flux, Beggs Brill, and Crisholm Baroczy. FluidFlow uses a modelling approach for pressure loss calculation which is a hybrid between the rigorous and empirical methods. Flow pattern maps are automatically generated by the software for each pipe in your system

4. Slurry Module (Non-Newtonian, Non-Settling Slurries, Settling Slurries and Pulp & Paper Stock Flow Systems).

This module can be used to model settling or non-settling non-newtonian fluids as well as Pulp & Paper Stock Flow Systems. Settling slurry calculation methods include Durand, Wilson-Addie-Sellgren-Clift (WASC), WASP, Liu Dezhong and the Four Component Model. Non-settling slurry calculations methods depend on rheology data which can be described as Power Law, Bingham Plastic, Hershel Buckley or Casson. Pulp & paper stock loss correlations include TAPPI & Moller K. FluidFlow allows users to study dilution effects in slurries.

5. Scripting Module (Dynamic Analysis)

The scripting module allows users to perform a wide range of dynamic simulations such as the study of tank fill/drain times based on a set of design pump operating conditions, analyze system pressure as demands vary, investigate system control philosophies, evaluate valve performance for variable speed pumps, flare stack depressurisation, analyze scale build-up in systems and study the effect on flow rate, optimize pump and system performance. You can write your own scripts using Basic or Pascal.

Clients & End Clients